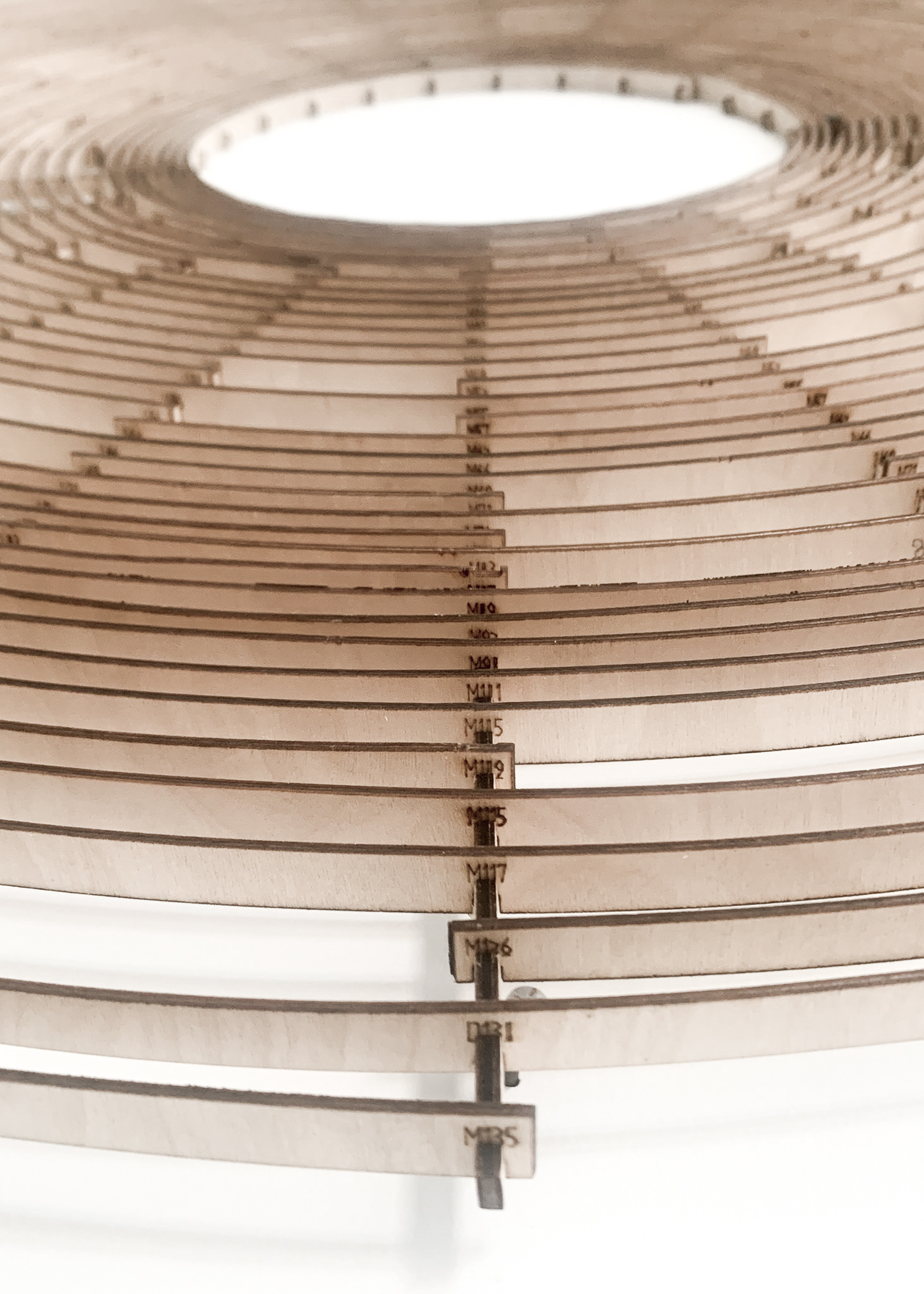

A parametric artwork derives its form from bending stress. Flexible aircraft plywood "ripples" are bent and held in place by rigid "rays", radiating from a central point.

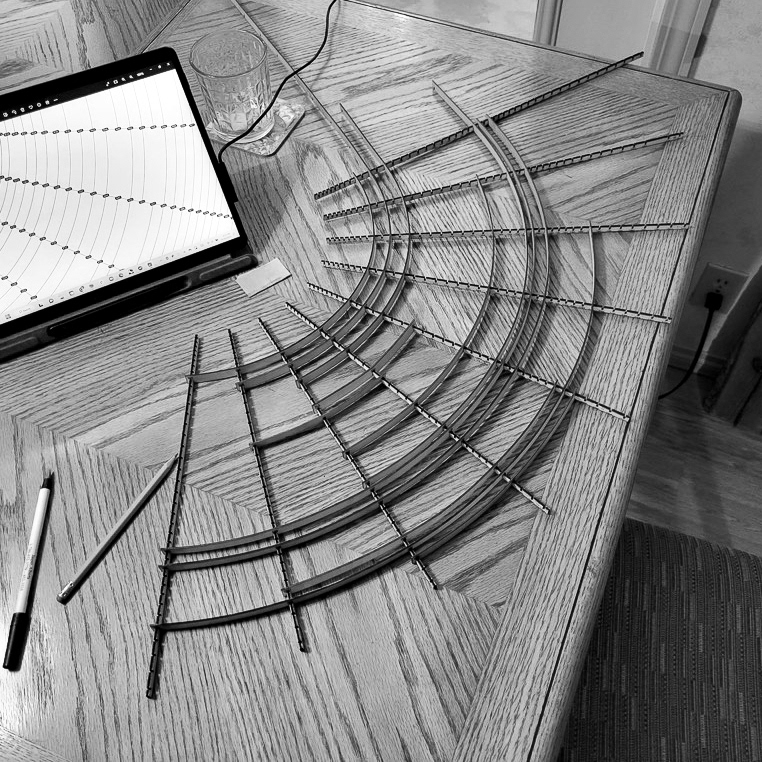

Below, a few initial studies explore the creation of stable shapes from flexible wooden strips.

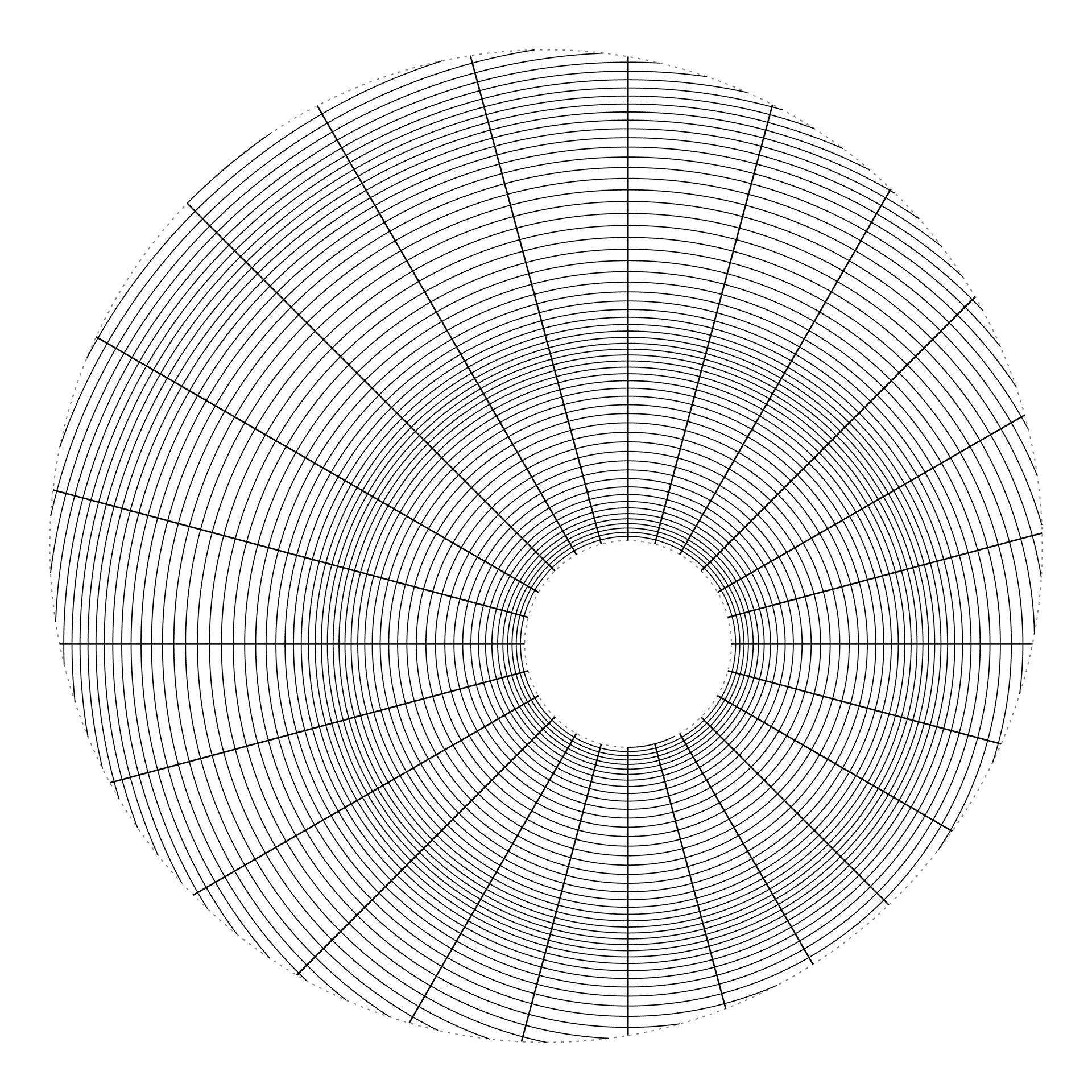

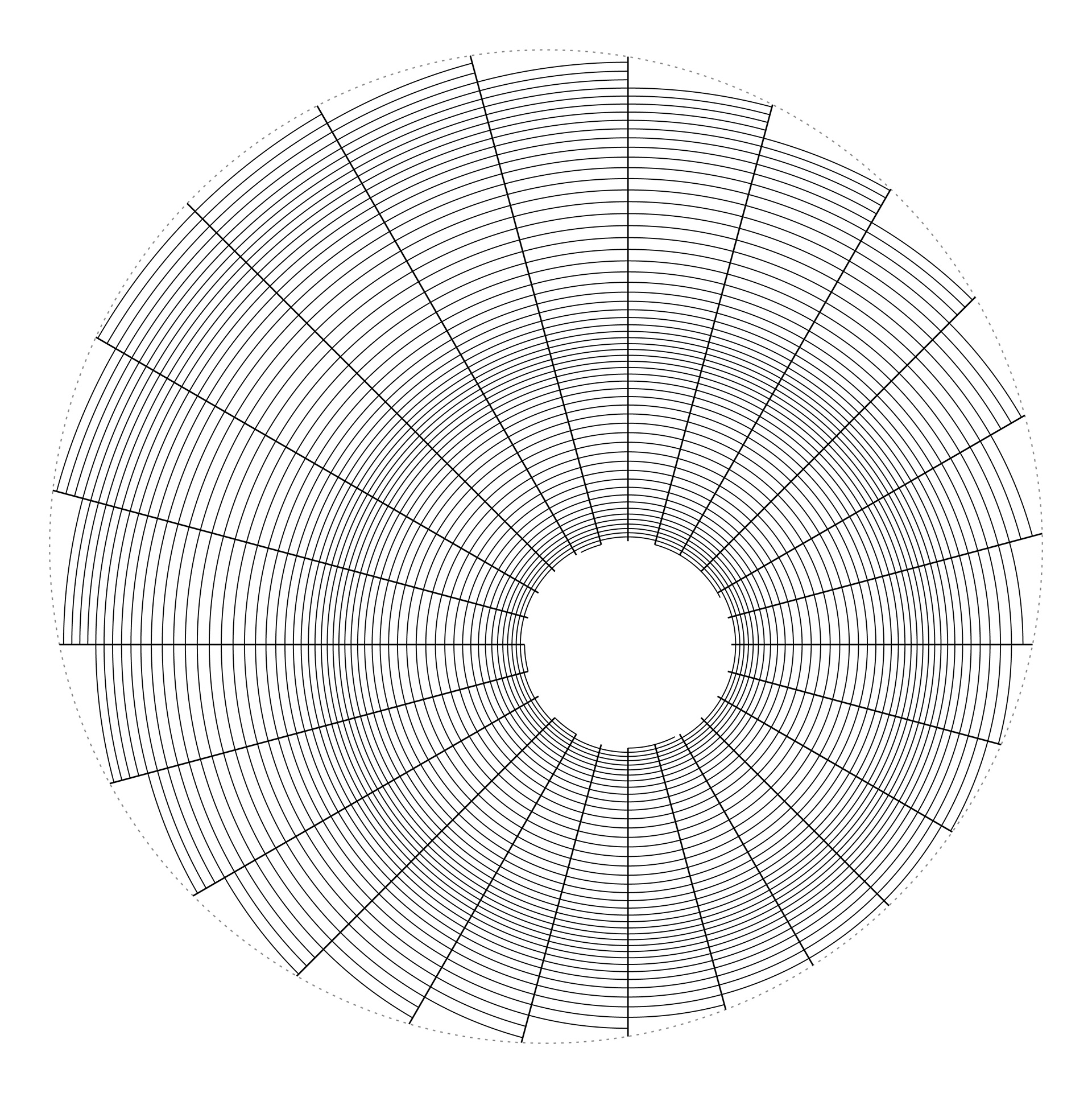

Embracing the structural concept and asymmetry, additional ripples and rays are introduced to the artwork via parametric model.

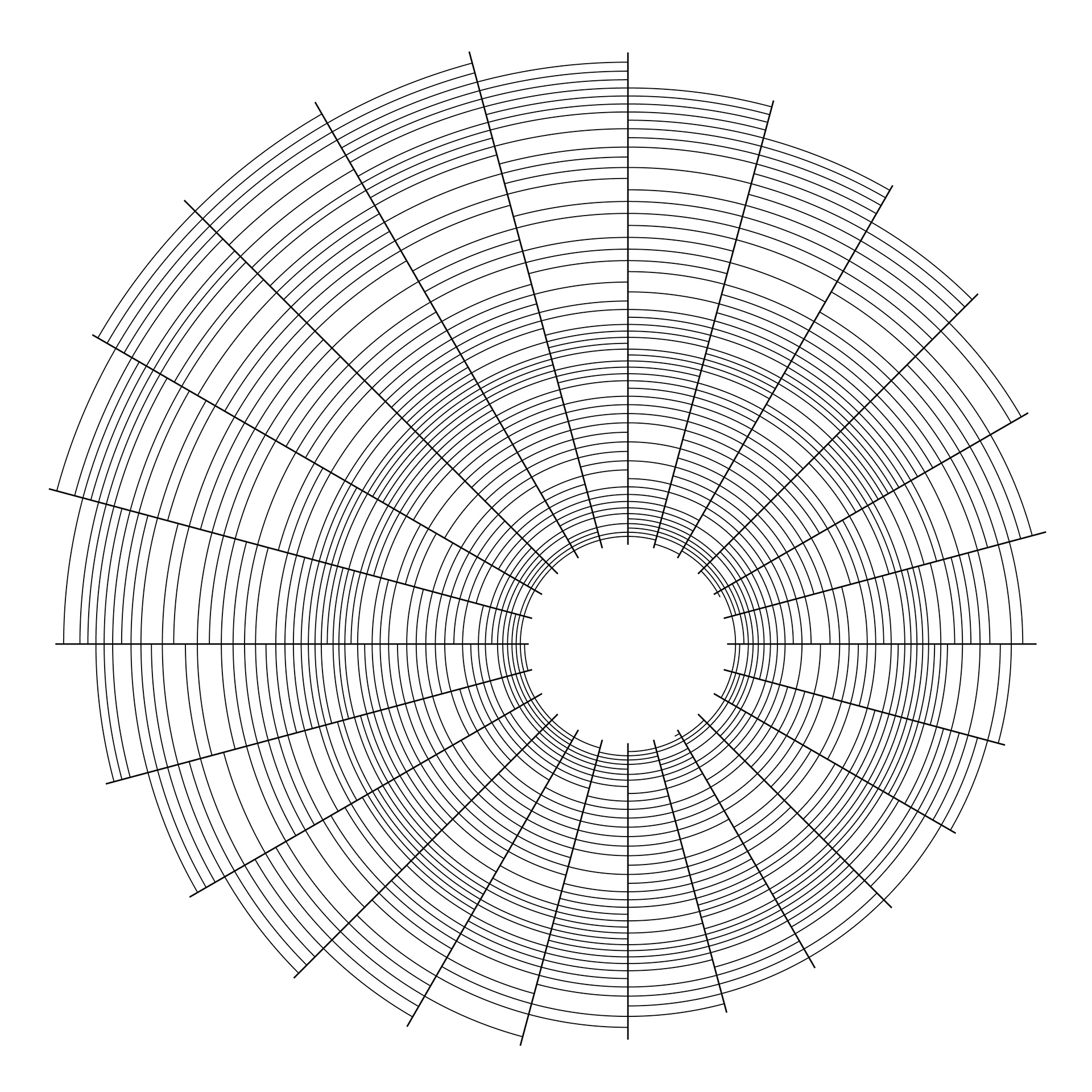

Define center, rays, and ripples.

Trim ripples via rays.

Remove ripple segments.

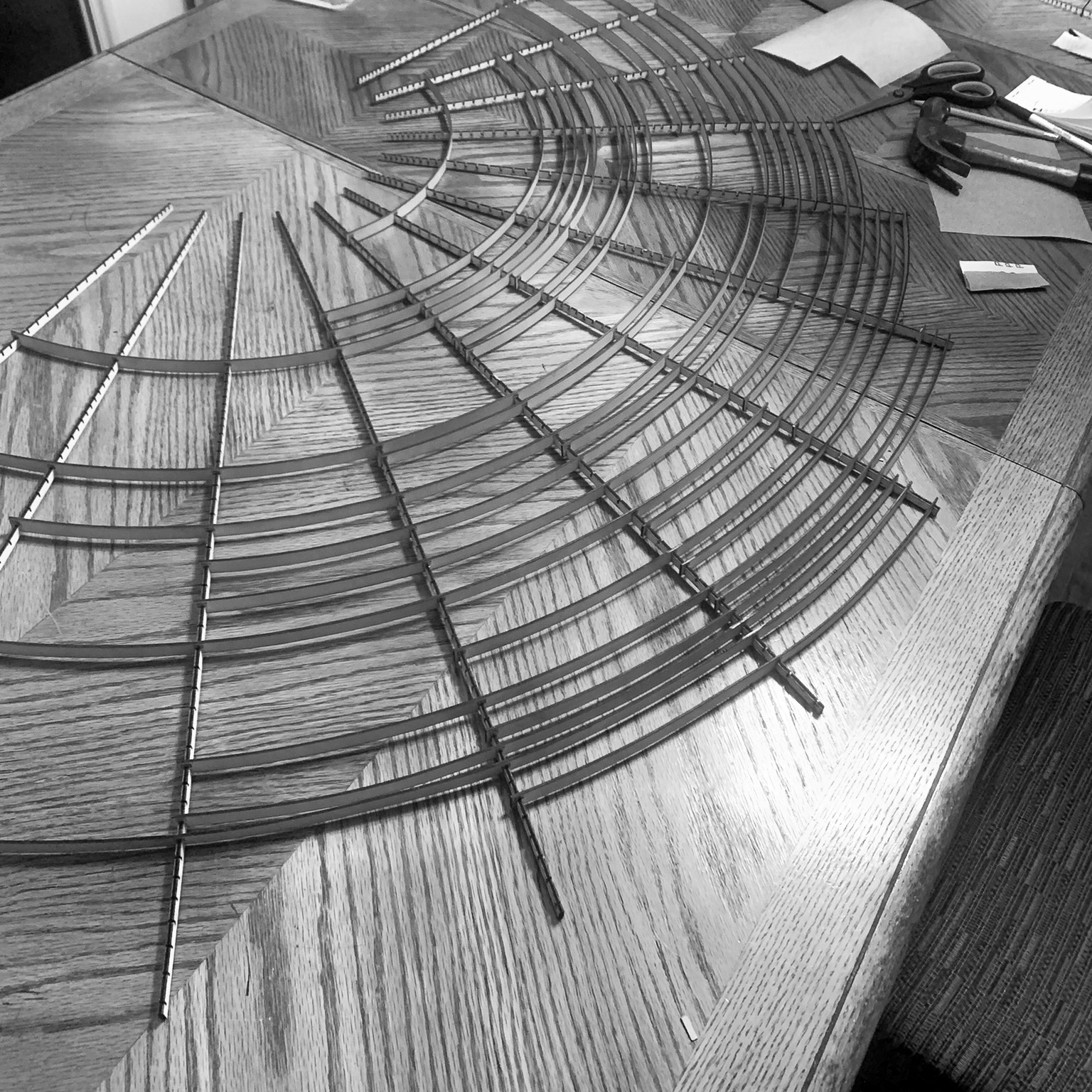

Several prototypes explored fabrication and connection methods, from threaded dowels to laser cut notches. Ultimately, laser cut notches provided the fixity, precision, and ease of assembly required.

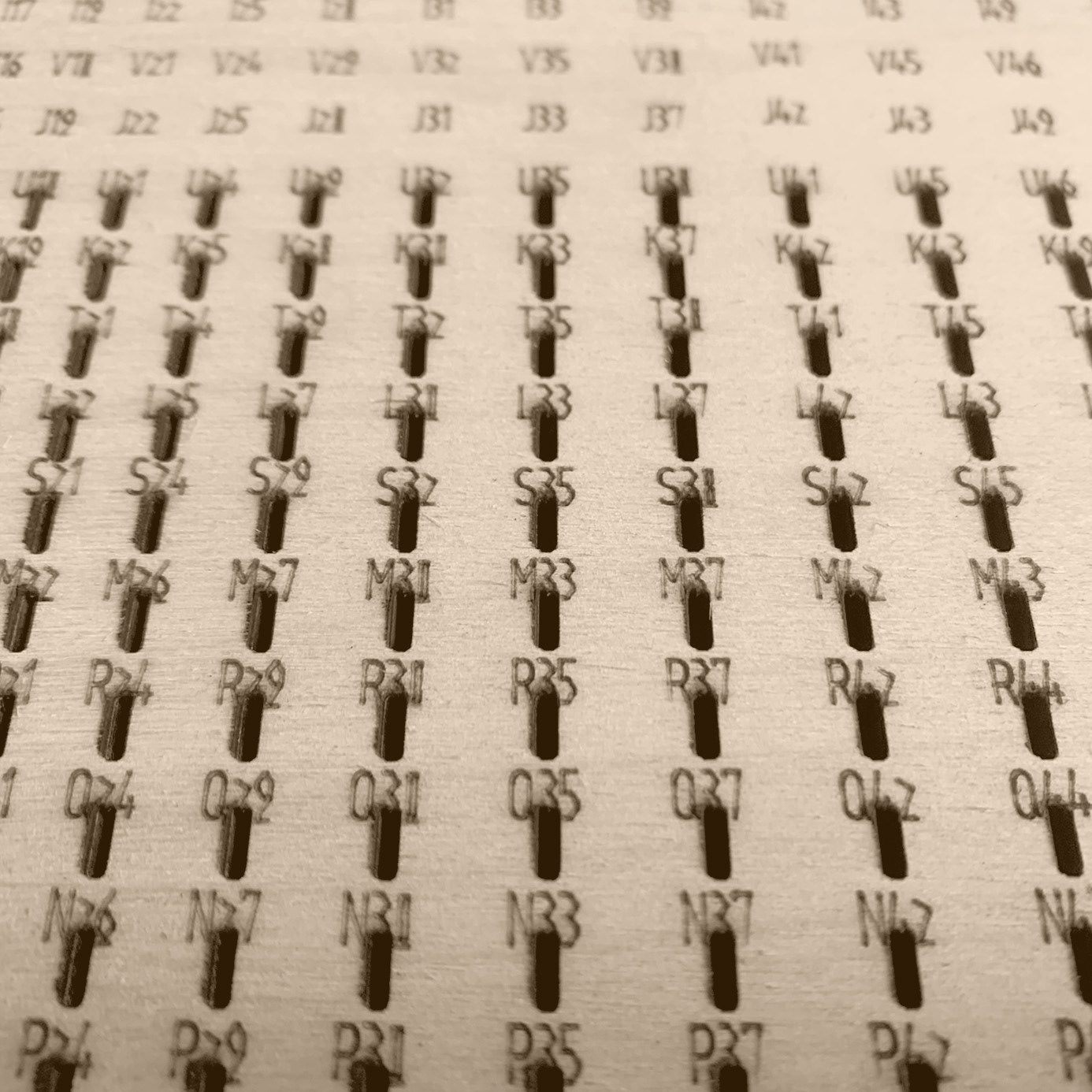

With a method of fabrication established, the ripples were entered into an optimization solver to reduce the following occurrences:

1. Ripples longer than the available material (red below).

2. Single segment ripples (yellow below).

3. Large concentrations of ripple gaps.

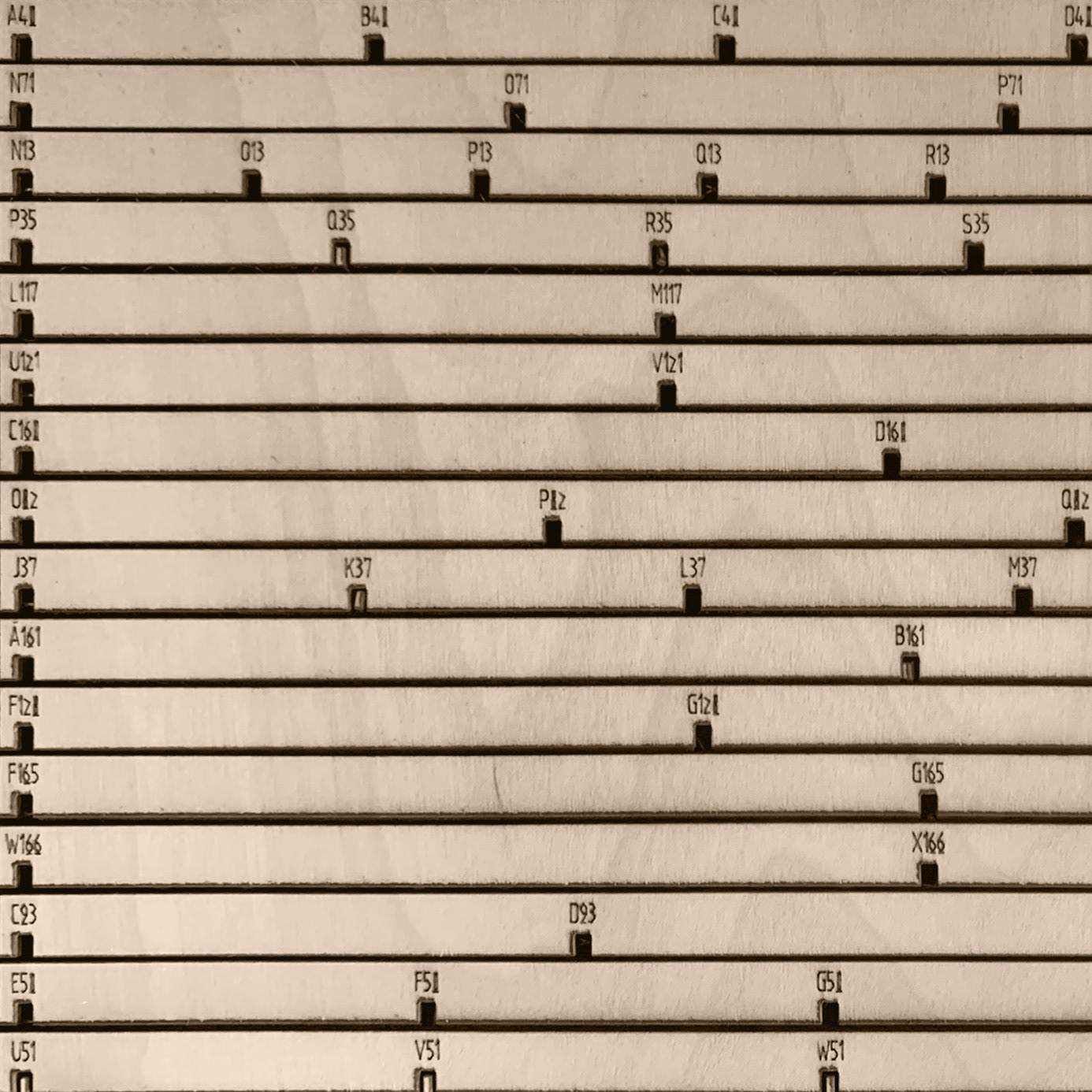

The wood rays and ripples were digitally unrolled for lasercutting. Engraved labels were added to ease assembly.

The artwork is quickly assembled from 24 rays and 190 ripples, notching together without any glue.

The resulting artwork ripples with arcs of light and shadow, weighing less than 10 lbs and stretching over 4 ft in diameter.